Polysaccharides多糖分子量降低

Our High Pressure Homogenizers provide high shear forces to effectively reduce the molecular weight of Polysaccharides. Our technology also offers the potential to target Polysaccharides viscosity properties and higher solubility at a neutral pH.

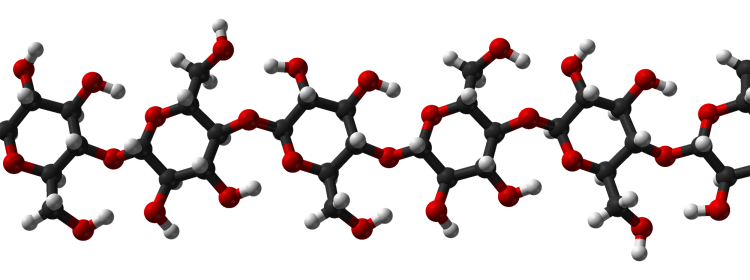

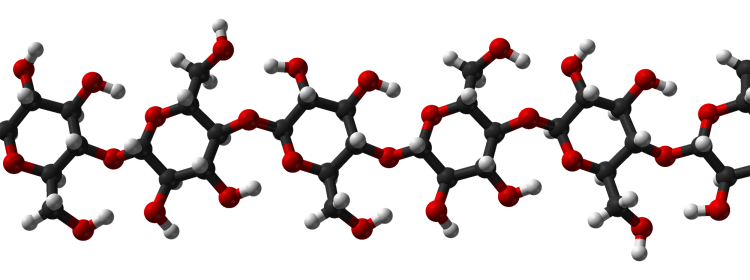

Polysaccharides are long chains of monosaccharides linked by glycosidic bonds. They are both biodegradable and biocompatible. Polysaccharides are used increasingly in the development of pharmaceuticals including as carriers for water-insoluble drugs, plasma expanders, immune stimulators and vaccine antigens.

Polysaccharides - our High Pressure Homogenizers

Benefits may include reduced viscosity, low polydispersity, higher solubility at a neutral pH and easier for post processing purification.

Industry-leading pressures to 60,000 psi (4200 bar) and processing from 1 ml to in excess of 1000 l/hour.

Our reliable systems are easy to clean and maintain with low ongoing ownership costs.

Our systems are easy to scale-up from Lab R&D scale to full production units.

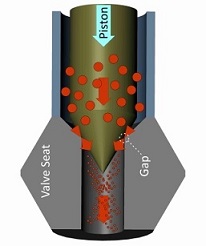

We offer interchangeable piston gap (PG) and microchannel devices (MCD) processing heads for our homogenizers - see below. We have polysaccharides processing customers using both types.

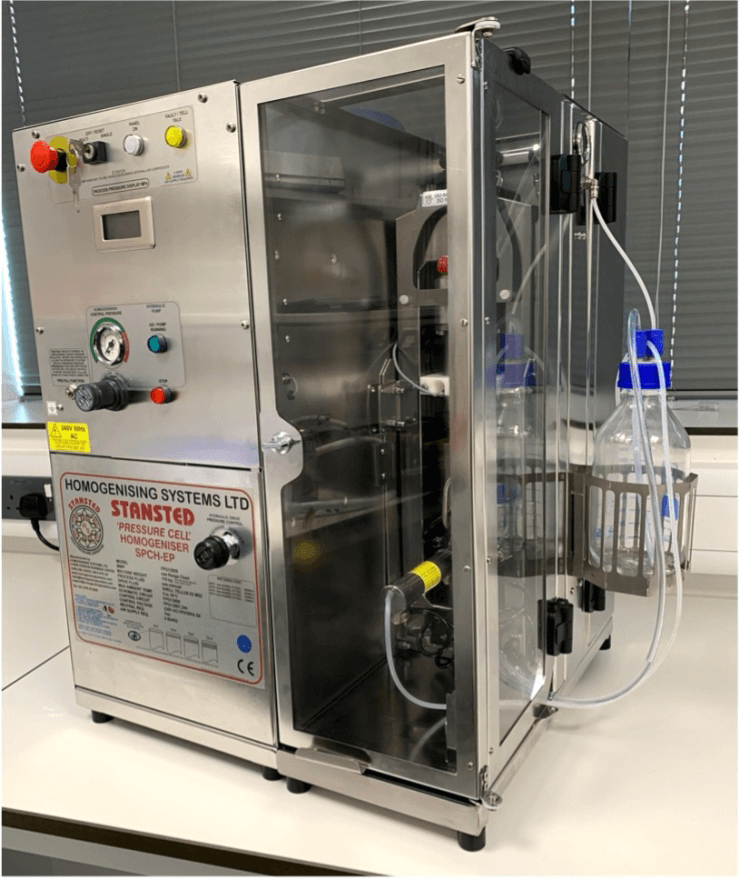

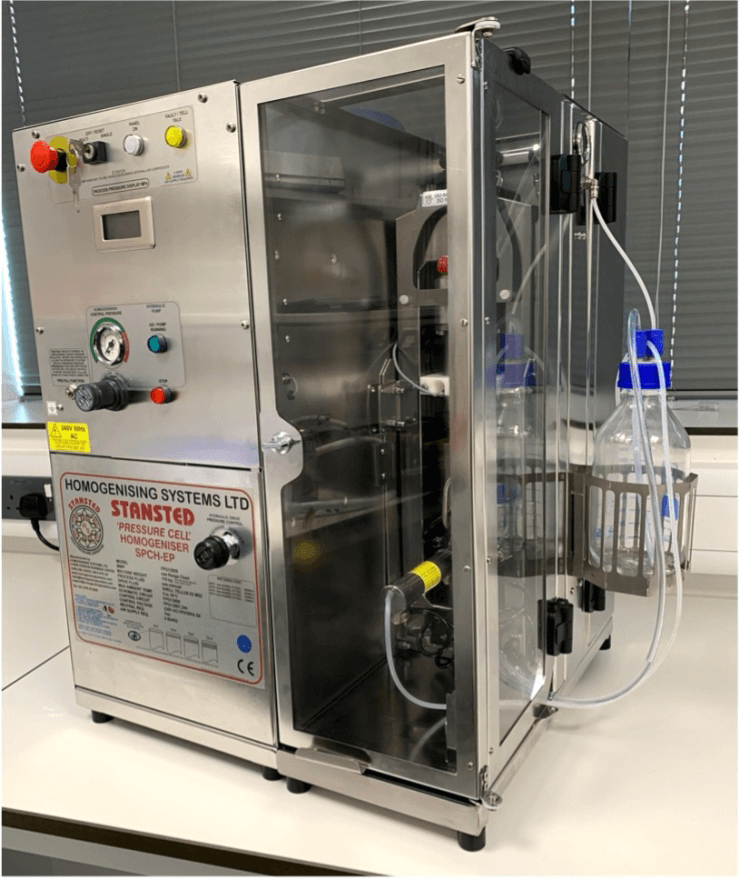

Pilot - Production Homogenizing System

Polysaccharides Production Homogenizer

Lab scale Homogenizer

Polysaccharides Lab Homogenizer

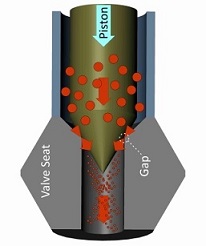

Piston Gap and Micro-Channel Device ('interaction chamber').

Homogenizing valve - spindle seat arrangement

Homogenizer valve - both Piston Gap and Micro Channel

3D structure of cellulose, a beta-glucan polysaccharide

我们的高压均质机提供高剪切力,以有效降低多糖的分子量。我们的技术还提供了多糖在中性pH下的粘度特性和更高的溶解度的潜力。

多糖是由糖苷键连接的单糖长链。它们都是可生物降解和生物兼容的。多糖越来越多地用于药物的开发,包括作为载体的水不溶性药物,血浆扩张剂,免疫刺激剂和疫苗抗原。

多糖-我们的高压均质器

好处可能包括降低粘度,低多分散性,在中性pH下更高的溶解度和更容易的后处理纯化。

行业领先的压力60000 psi (4200 bar)和处理从1ml到超过1000升/小时。

我们可靠的系统易于清洁和维护,持续拥有成本低。

我们的系统很容易从实验室研发规模扩展到完整的生产单位。

我们为我们的均质机提供可互换的活塞间隙(PG)和微通道设备(MCD)-见下文。我们有多糖加工客户使用这两种类型。

中试生产均质系统

多糖生产均质器

实验室规模均质器

多糖实验室均质器

活塞间隙和微通道装置(“交互室”)。

均质阀-主轴座布置

均质阀-活塞间隙和微通道

纤维素的三维结构,β -葡聚糖多糖