Liposomes脂质体制备

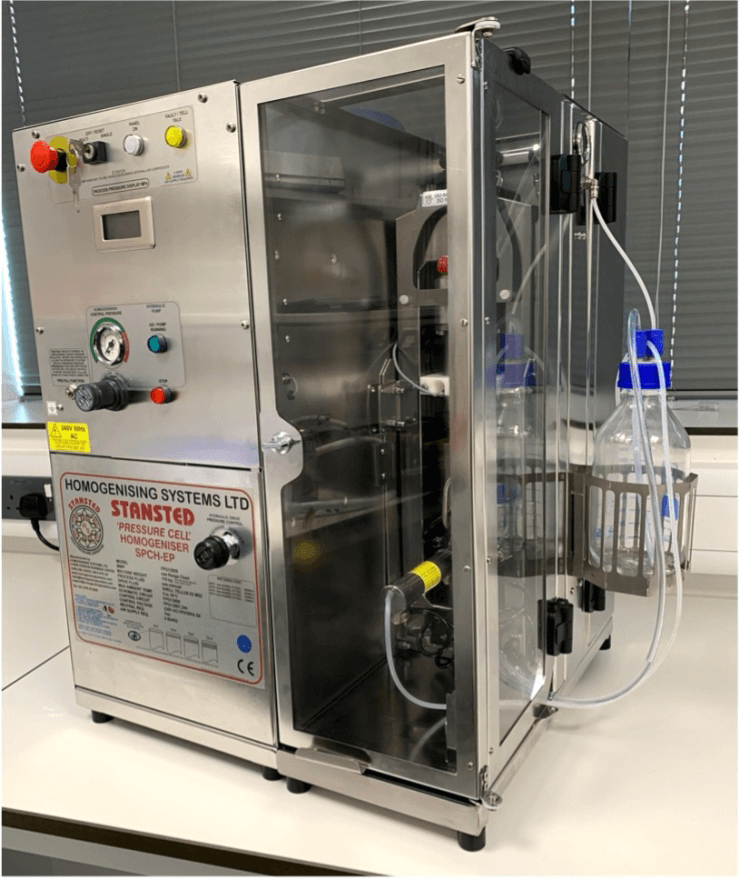

Our high shear, High Pressure Homogenizers excel at liposomes preparation because of their vesicle disruption proficiency that enables rapid reduction of size. This can be achieved at both Lab and Production scale with repeatable results.

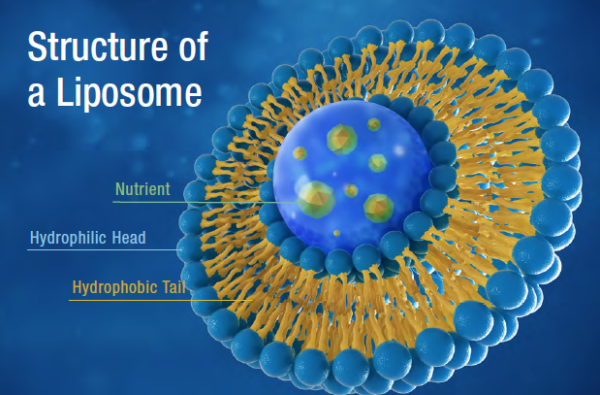

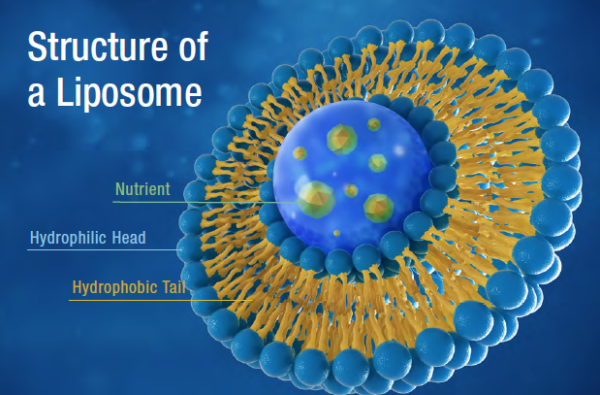

Liposomes can be used as a vehicle for administration of pharmaceutical drugs and nutrients as they are able to encapsulate and deliver the active ingredients to targeted areas.

Generally, four basic stages are involved in liposome preparation and there is a choice of different methods within each stage which influence the liposome characteristics.

This summary page focuses on our method of (mechanical) high pressure homogenization (HPH) as provided by our industry-leading homogenising systems.

Liposomes - our High Pressure Homogenizers

Provide rapid reduction of vesicle size and lamellarity to achieve smaller sizes whilst narrowing the distribution.

HPH also presents the opportunity to load the liposomes, locating hydrophilic active substances within the aqueous vesicle core.

Ultra high pressures to 60,000 psi (4200 bar) and processing from 1 ml to 35ml in the Laboratory up to flow rates in excess of 1000 l/hour.

Easy to scale - from Lab to full production systems for continuous processing with repeatable results.

Multiple options for temperature control - both pre-processing and post processing.

Piston Gap and Micro-Channel Device (interaction chamber).

We think we are unique in that we offer interchangeable piston gap (PG) and micro-channel devices (MCD) processing heads for systems. For liposome preparation both types can be effective but we recommend (for production applications) that both technologies are tested.

Vesicle size reduction is a function of pressure, valve type (PG or MCD) and formulation. Typically sizes from micron level to below 50 nanometers / nm can be achieved.

Laboratory

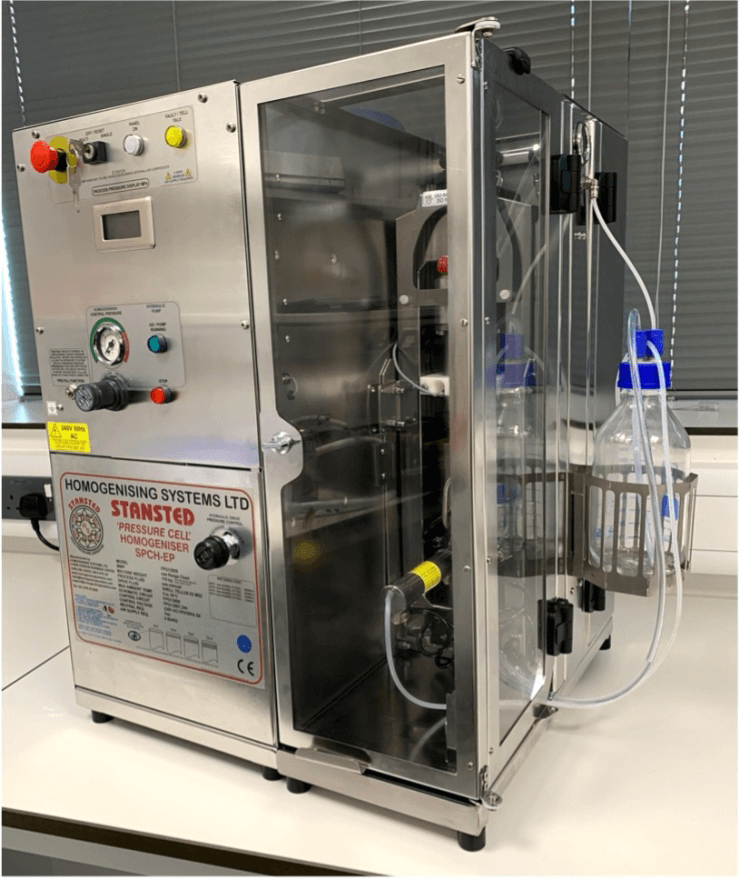

High Pressure Laboratory Homogenizer for Lipsome formulation

Highly versatile, fully featured bench top instruments with pressures to 60,000 psi (410 MPa, 4200 bar).

Pilot - R&D

High Pressure Pilot Homogenizer for Lipsome preparation

For R&D and smaller scale production up to 125 l/hr.

Production Scale

Lipsome Production Homogenizer system

Full scale production systems with flow rates up to 1000 l/hr offering unrivalled performance.

我们的高剪切,高压均质机擅长脂质体制备,因为他们的囊泡破坏的熟练程度,使大小迅速缩小。这可以在实验室和生产规模实现,结果可重复。

脂质体可以作为药物和营养的管理载体,因为它们能够封装和运送有效成分到目标区域。

一般来说,脂质体的制备有四个基本阶段,每个阶段有不同的方法选择,这将影响脂质体的特性。

本总结页面重点介绍了由我们行业领先的均质系统提供的(机械)高压均质(HPH)方法。

脂质体-我们的高压均质器

提供快速减少囊泡大小和层状结构,以实现更小的尺寸,同时缩小分布。

HPH也提供了装载脂质体的机会,定位在水泡核内的亲水活性物质。

超高压至60000 psi (4200 bar),在实验室处理从1毫升到35毫升,流量超过1000升/小时。

易于扩展-从实验室到完整的生产系统,连续处理可重复的结果。

多种温度控制选项-预处理和后处理。

活塞间隙和微通道装置(交互室)。

我们认为我们是独一无二的,因为我们为系统提供可互换的活塞间隙(PG)和微通道设备(MCD)处理头。对于脂质体制备,这两种方法都有效,但我们建议(对于生产应用)对两种技术都进行测试。

泡囊尺寸的减小与压力、阀门类型(PG或MCD)和配方有关。通常可以实现从微米级到50纳米/纳米以下的尺寸。

实验室

用于脂质体配方的高压实验室均质机

高度通用,功能齐全的台式仪器,压力可达60000 psi (410 MPa, 4200 bar)。

中试——研发

用于脂质体制备的中试型高压均质机

用于研发和小型生产,最高可达125升/小时。

生产规模

脂质体生产均质器系统

全规模生产系统的流量高达1000升/小时,提供无与伦比的性能。