IJM Nanoscaler脂质纳米颗粒(lnp)生产和配方系统

IJM Nanoscaler脂质纳米颗粒(lnp)生产和配方系统

THE IJM NANOSCALER: A BENCHTOP SYSTEM FOR LIPID NANOPARTICLE FORMULATION

IJM NANOSCALER: 脂质纳米颗粒配方的台式系统

KNAUER's new benchtop IJM NanoScaler system is designed for lab-scale lipid nanoparticle formu-lation – allowing scientists to screen for optimal process parameters to formulate API-containing lipid nanoparticles.

KNAUER的新型台式IJM NanoScaler系统是为实验室规模的脂质纳米颗粒配方设计的,允许科学家筛选最佳的工艺参数,以制备含API的脂质纳米颗粒。

The IJM NanoScaler is made for research and development as well as preclinical and smallscale production of lipid nanoparticles. Equipped with our lipid nanoparticle producing Impingement Jets Mixing (IJM) technology the NanoScaler allows researchers to optimize encapsulation conditions for their APIbased therapy before scaling up the process to run on a larger IJM NanoProducer unit.

IJM NanoScaler用于脂质纳米颗粒的研究和开发以及临床前和小规模生产。配备了我们的脂质纳米颗粒产生冲击射流混合(IJM)技术,纳米缩放器允许研究人员优化基于API的治疗的封装条件,然后将工艺扩大到更大的IJM NanoProducer单元。

The NanoScaler is made for low sample consumption so as not to waste valuable API. Its small footprint means it can comfortably sit on the benchtop of a research and development lab. The system comes with five different KNAUER Impingement Jets Mixers to help researchers determine which conditions result in the optimum level of API encapsulation. These active pharmaceutical ingredients include complex or delicate API like RNA, mRNA, siRNA, and DNAbased molecules, or products that need specific entry into target cells. In addition researchers can use their own custom mixing unit and benefit from the flexibility of the system setup. The formulation process can be remotely controlled by software; ran from a conventional PC or laptop, or even a tablet.

NanoScaler是为低样品消耗而制造的,从而不浪费有价值的API。它占地面积小,可以舒适地坐在研发实验室的工作台上。该系统配备了五种不同的KNAUER撞击射流混合器,以帮助研究人员确定哪种条件可以产生API封装的最佳水平。这些活性药物成分包括复杂或精细的API,如RNA、mRNA、siRNA和基于DNA的分子,或需要特定进入靶细胞的产品。此外,研究人员可以使用自己的定制混合单元,并从系统设置的灵活性中受益。配方过程可通过软件远程控制;从传统的个人电脑或笔记本电脑,甚至平板电脑上运行。

Key parameters

PDI: between 0.1 and 0.2

Particle size:80–90 nm

Encapsulation Efficiency > 90 %

关键参数

PDI:在0.1到0.2之间

粒度:80 - 90nm

封装效率> 90%

LNP FORMULATIONS FOR PRE-CLINICAL RESEARCH AND PRODUCTION

用于临床前研究和生产的LNP配方

The NanoScaler can be used to produce lipidencapsulated nucleotides at a range from 1 ml to hundreds of milliliters meaning the system is perfect for:

NanoScaler可以用于生产1毫升到数百毫升的脂包核苷酸,这意味着该系统是完美的:

Proof of concept testing and process optimization – pure nucleotides are an expensive resource. Carry out proof of concept testing and process optimization at the 1,000 μl scale to avoid wastage.

概念验证测试和工艺优化-纯核苷酸是一种昂贵的资源。在1000 μl范围内进行概念验证测试和工艺优化,以避免浪费。

Pre-clinical trials – Preclinical testing can be carried out using 100 ml of nucleotides such as, for in vitro studies to determine the tolerability, efficacy and potential toxicity of the mRNA therapy of interest.

临床前试验-可使用100毫升核苷酸进行临床前试验,用于体外研究,以确定感兴趣的mRNA治疗的耐受性、疗效和潜在毒性。

Small scale production – Once proofofconcept and safety testing have been successfully conducted, production of LNP encapsulated API´s can even be carried out at up to 0.1 Liter per minute with the IJM NanoScaler or using KNAUER’s scaledup IJMNanoProducer Units.

小规模生产一旦概念验证和安全测试成功进行,LNP封装API的生产甚至可以以每分钟0.1升的速度进行,使用IJMNanoScaler或使用KNAUER的放大IJMNanoProducer单元。

Which formulation parameters can be tested using the NanoScaler?

The IJM NanoScaler enables the scouting of several key process parameters during the lipid nanoparticle encapsulation stage.

哪些配方参数可以用NanoScaler测试?

IJMNanoScaler能够在脂质纳米颗粒封装阶段探测几个关键的工艺参数。

Mixing unit – The five different Impingement Jets Mixer geometries, plus the opportunity to integrate a custom mixing unit, allow determination of the process conditions required to achieve maximum efficiency, optimal particle size and homogeneous size distribution.

混合单元-五种不同的冲击射流混合器几何形状,加上集成自定义混合单元的机会,允许确定所需的工艺条件,以实现最高效率,最佳粒度和均匀的粒度分布。

Mixing flow rate and ratio – Determine how the specific physicochemical properties of the lipid nanoparticle are impacted by the mixing flow – find out which flow rates and ratio provide optimum lipid nanoparticle encapsulation.

混合流量和比例-确定脂质纳米颗粒的具体物理化学性质如何受到混合流量的影响-找出哪个流量和比例能提供最佳的脂质纳米颗粒封装。

Lipid formulation – Testing of new lipid formulations, for example lipids with embedded antibodies for targeted medicines, is possible using the NanoScaler. Determine the conditions required to ensure lipid nanoparticle encapsulation takes place before producing the therapy at scale for trials.

脂质配方——测试新的脂质配方,例如含有靶向药物抗体的脂质配方,可以使用NanoScaler。确定所需的条件,以确保脂质纳米颗粒包封,然后进行大规模生产治疗试验。

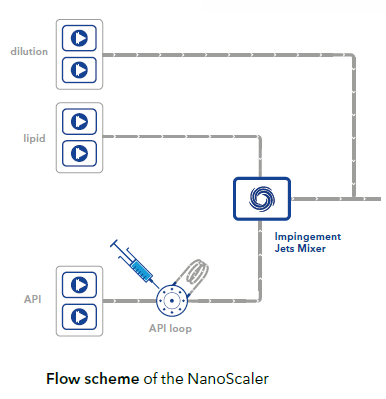

Dilution protocols – The liquid flow path of the NanoScaler can be configured to either include or bypass the dilution step following lipid nanoparticle formation – allowing scientists to produce formulations at the exact concentration required.

稀释方案——NanoScaler的液体流动路径可以配置为包括或绕过脂质纳米颗粒形成后的稀释步骤——使科学家能够在所需的精确浓度下生产配方。

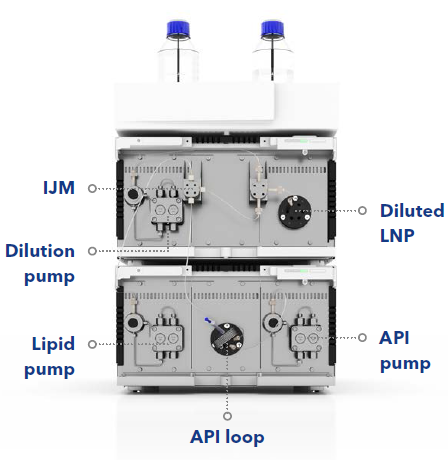

Number of impingement jets mixers: 5, IJM 15 manual selection

Number of pumps:3

Number of flow meters:on request

Number of valves:2

Process connection inlet**:1/8" OD, 2.1 mm ID FEP tubing (UNF 1/428 thread, flat bottom)

Process connection outlet**:1/16" OD, 0.5 mm ID PEEK tubing (UNF 1032, thread coned)

Volumetric flow rate:up to 0.1 l/min

Volumetric flow rate:up to 6 l/h

Maximum operating pressure***:140 bar (2030 psi)

Liquid temperature range:4–60 °C (39.2–140 °F)

Wetted materials:stainless steel, PEEK, titanium, FFKM, PTFE (GFP 55), aluminum oxide, ruby, sapphire, ETFE, PETP, zirconium oxide, Hastelloy, FEP

Software:CDS optional available 21 CFR part 11 and Gamp 5 compliant

Interfaces:LAN, pin header connectors

Power supply:docking station (including pumps and valves): 100–240 VAC single phase, 50/60 Hz; PC: 100–240 VAC single phase, 50/60 Hz; Monitor: 100–240 VAC single phase, 50/60 Hz; Network switch: 100240 VAC single phase, 50/60 Hz, 12V DC Power supply

Power consumption (per device):docking station (including pumps and valves): maximum 130 W; PC: 1000 W; monitor: 380 W; network switch: 50 W

Ambient conditions:temperature range: 4–40 °C; 39.2−104 °F; below 90 % humidity (noncondensing)

Dimensions (W x H x D):361 x 501 x 603 mm

Net weight (approx.):35 kg

API-predilution and quenching:only quenching

Customized technical documentation, order-and article-related:on request

Factory acceptance test:on request

Site acceptance test:on request

撞击射流混合器数量:5个,IJM 1-5手动选择

泵的数量:3

流量计数量:按要求提供

阀门数量:2

工艺连接入口**:1/8”外径,2.1 mm ID FEP管(UNF 1/4-28螺纹,平底)

工艺连接出口**:1/16" OD, 0.5 mm ID PEEK管(UNF 10-32,螺纹锥形)

体积流量:可达0.1升/分钟

容积流速:高达6升/小时

最大工作压力***:140 bar (2030 psi)

液体温度范围:4-60°C(39.2-140°F)

湿化材料:不锈钢,PEEK,钛,FFKM, PTFE (GFP 55),氧化铝,红宝石,蓝宝石,ETFE, PETP,氧化锆,哈氏合金,FEP

软件:可选的cd 21 CFR part 11和Gamp 5兼容

接口:局域网,引脚头连接器

电源:对接站(包括泵和阀门):100-240伏单相,50/60赫兹;PC: 100-240伏单相,50/60赫兹;显示器:100-240伏单相,50/60赫兹;网络开关:100-240伏单相,50/ 60hz, 12V DC电源

功率消耗(每台设备):对接站(包括泵和阀门):最大130w;电脑:1000 W;监控:380 W;网络交换机:50w

环境条件:温度范围:4-40°C;39.2−104°F;湿度低于90%(不凝结)

尺寸(宽×高×深):361 × 501 × 603毫米

净重(约):35公斤

API预稀释淬火:仅淬火

定制技术文档,与订单和产品相关:按需提供

工厂验收测试:按要求进行

现场验收试验:按要求进行