IJM SingleCore NanoProducer脂质纳米颗粒(lnp)生产和配方系统

IJM SingleCore NanoProducer脂质纳米颗粒(lnp)生产和配方系统

IJM SingleCore NanoProducer

SYSTEMS FOR LIPID NANOPARTICLE (LNP) PRODUCTION AND FORMULATION

The number of parallel units depends on the application. Also, the number of pumps, flow meters, jets mixers and pipes can be adapted to the required conditions and scale. All IJM NanoProducers are built in a stainless steel frame on casters and are suitable for CIP cleaning procedures in pharmaceutical production. The IJM DoubleCore NanoProducer contains two parallel mixing units. Each unit consists of four pumps. Concentrated Active Pharmaceutical Ingredient (API) solution is diluted first and then mixed with the organic phase. Finally, the mixture is quenched in a third mixer. Both units can be operated independently. The IJM NanoProducer can be configured with up to eight parallel mixing units depending on the customer requirements. Each unit consists of two pumps to deliver lipid and API streams, two flow meters for flow control and one jet mixer. Depending on the configuration, the predilution of the API and quenching can be performed for the combined flow of all units in one process step outside the Impingement Jets Mixing (IJM) NanoProducer.

IJM SingleCore NanoProducer脂质纳米颗粒(lnp)生产和配方系统

并联单元的数量取决于应用程序。此外,泵、流量计、射流混合器和管道的数量可以适应所需的条件和规模。所有IJM NanoProducer建立在一个不锈钢框架上的脚轮,适合在制药生产的CIP清洗程序。IJM DoubleCore NanoProducer包含两个并行混合单元。每个机组由四个泵组成。浓缩活性药物成分(API)溶液首先稀释,然后与有机相混合。最后,混合物在第三个混合器中被淬火。两个装置都可以独立运行。根据客户的要求,IJM NanoProducer可以配置多达8个并行混合单元。每个单元包括两个泵输送脂质和API流,两个流量计用于流量控制和一个喷射混合器。根据配置,API的预稀释和淬火(quenching)可以在撞击射流混合(IJM)NanoProducer以外的一个工艺步骤中对所有单元的组合流进行。

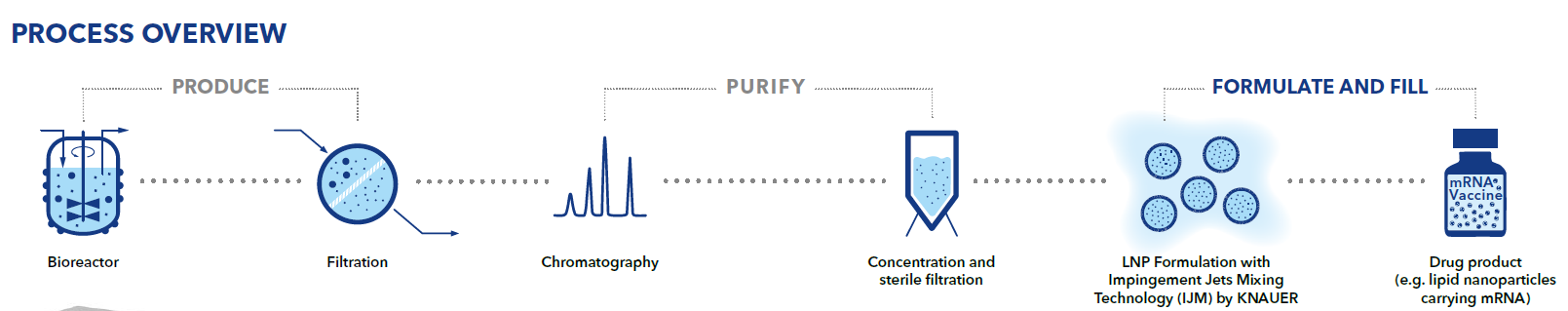

THE TECHNOLOGY

Impingement Jets Mixing Technology (IJM) enables the formulation and production of highquality lipid nanoparticles carrying API (e.g. for mRNA vaccines). The encapsulation process of active pharmaceutical ingredients with lipids is based on Impingement Jets Mixing Technology, where two streams collide at high velocity in a jet mixing chamber. One of the streams contains the lipids in organic solvents and the other stream the API in water.

技术

撞击射流混合技术(IJM)可以配制和生产携带API的高质量脂质纳米颗粒(例如用于mRNA疫苗)。活性药物成分与脂类的封装过程是基于撞击射流混合技术,即两股流在射流混合室中高速碰撞。其中一条流包含有机溶剂中的脂类,另一条流包含水中的API。

The mixing at high velocity reduces the solubility of the lipids so that homogenous nanoparticles are formed. The quality of nanoparticles depends on the streams‘ flow stability, the mixer geometry and the fluid velocities. As a final step, the mixture is quenched to stop particle growth.

高速的混合降低了脂质的溶解度,从而形成了均匀的纳米颗粒。纳米粒子的质量取决于流体的流动稳定性、混合器的几何形状和流体速度。作为最后一步,混合物被淬火(quenched)以阻止粒子生长。

System for LNP formulation consisting of:

KNAUER highpressure dosing pumps 80P

Coriolis flow meters

KNAUER IJM mixers

Inlet manifolds for lipid/ethanol mixture and API/buffer mixture

Outlet manifold for LNP solution

Backseal washing system

Frame (stainless steel system 1.4301)

Installation & familiarization by KNAUER

A customized technical documentation which is order and articlerelated

Customer Service before, during and after the set up

Capillary customization and labeling

FAT (Factory Acceptance Test at KNAUER Berlin)

SAT (Site Acceptance Test at customer site)

LNP配方系统包括:

KNAUER高压给料泵80P

Coriolis 流量计

KNAUER IJM混合器

用于脂质/乙醇混合物和API/缓冲混合物的入口歧管

LNP溶液的出口歧管

Back-seal清洗系统

框架(不锈钢系统1.4301)

KNAUER的安装和熟悉

与订单和产品相关的定制技术文档

安装前、安装中、安装后的客户服务

毛细管定制和标签

FAT (KNAUER Berlin工厂验收测试)

SAT(客户现场验收测试)

IJM SingleCore NanoProducer

Number of impingement jets mixers: 1

Number of pumps:4

Number of flow meters:4

Number of valves:1

Process connection inlet**:1/2" Triclamp (4 inlets)

Process connection outlet**:1/2" Triclamp (1 outlet)

Volumetric flow rate:up to 1 l/min

Volumetric flow rate:up to 60 l/h

Maximum operating pressure***:95bar (1378 psi)

Liquid temperature range:4–60 °C (39.2–140 °F)

Wetted materials:stainless steel, PEEK, titanium, FFKM, PTFE (GFP 55), aluminum oxide, ruby, sapphire, EPDM, zirconium oxide, POM, hastelloy

Software:CDS, 21 CFR part 11 and GAMP 5 compliant

Interfaces:pump: LAN, RS232, pin header connectors; flow meter: RS232 + FLOWBUS™; valve drive: LAN

Power supply:pump: 100–240 VAC single phase, 50/60 Hz; flow meter: 115/230 VAC single phase,

50/60 Hz 24V DC Power supply; valve drive: 115/230 VAC single phase, 50/60 Hz 24V DC Power supply; PC: 100–240 VAC single phase, 50/60 Hz; monitor: 100–240 VAC single phase, 50/60 Hz; network switch: 100–240 VAC single phase, 50/60 Hz, 12 V DC Power supply

Power consumption (per device):pump: maximum 320 W; flow meter: 3 W; valve drive: 65 W; PC: 1000 W; monitor: 380 W; network switch: 50 W

Ambient conditions:temperature range: 4–40 °C; 39.2−104 °F; below 90 % humidity (noncondensing)

Dimensions (W x H x D):900x 915 x 700 mm

Net weight (approx.):150 kg

API-predilution and quenching:Yes

Customized technical documentation, order-and article-related:Yes

Factory acceptance test:Yes

Site acceptance test:Yes

撞击射流混合器数量:1

泵的数量:4

流量计数量:4个

阀门数量:1

工艺连接入口**:1/2"Triclamp(4个入口)

工艺连接插座**:1/2”Triclamp(1个出口)

容积流速:可达1升/分钟

容积流速:高达60升/小时

最大工作压力***:95bar (1378 psi)

液体温度范围:4-60°C(39.2-140°F)

湿性材料:不锈钢,PEEK,钛,FFKM, PTFE (GFP 55),氧化铝,红宝石,蓝宝石,EPDM,氧化锆,POM,哈氏合金

软件:CDS, 21 CFR part 11和gamp5兼容

接口:泵:LAN, RS-232,引脚头连接器;流量计:RS-232 + flow - bus™;阀门驱动:局域网

电源:泵:100-240伏单相,50/60赫兹;流量计:115/230伏单相,50/ 60hz 24V DC电源;阀门驱动:115/230 VAC单相,50/60 Hz 24V直流电源;PC: 100-240伏单相,50/60赫兹;显示器:100-240伏单相,50/60赫兹;网络开关:100-240伏单相,50/ 60hz, 12v DC电源

功耗(每台设备):泵:最大320w;流量计:3w;阀传动:65w;电脑:1000 W;监控:380 W;网络交换机:50w

环境条件:温度范围:4-40°C;39.2−104°F;湿度低于90%(不凝结)

尺寸(宽×高×深):900 × 915 × 700毫米

净重(约):150公斤

API-预稀释和淬火(quenching):是的

与订单和产品相关的定制技术文档:是

工厂验收测试:是的

现场验收测试:是的