Vaccine adjuvant疫苗佐剂开发

High pressure, high shear Homomogenizers for vaccine adjuvant development at both R&D and production scale. Efficient processing with the smallest particle sizes and narrow particle size distribution.

Adjuvants are commonly employed to enhance the efficacy of a vaccine and thereby help increase the resulting immune response in a patient.

Our industry-leading technology can create nanoparticles with controlled droplet sizes and distribution curves that can be sterile filtered with minimal yield losses.

Vaccine adjuvants - our High Pressure Homogenizers

Easy to scale-up - from Lab R&D to full production systems - up to 1000 l/h - with with repeatable results.

Controllable, industry-leading pressures up to 4200 bar (60,000 psi / 420 MPa).

Sophisticated temperature control options.

CIP and SIP capability. Provision of DQ/IQ/OQ documentation.

Easy to clean and sterlize. CIP and SIP capability.

Easy to maintain with low ongoing ownership costs.

Precise high shear creating smaller, target particles with a narrow size distribution.

Lab Homogenizer for Vaccine R&D

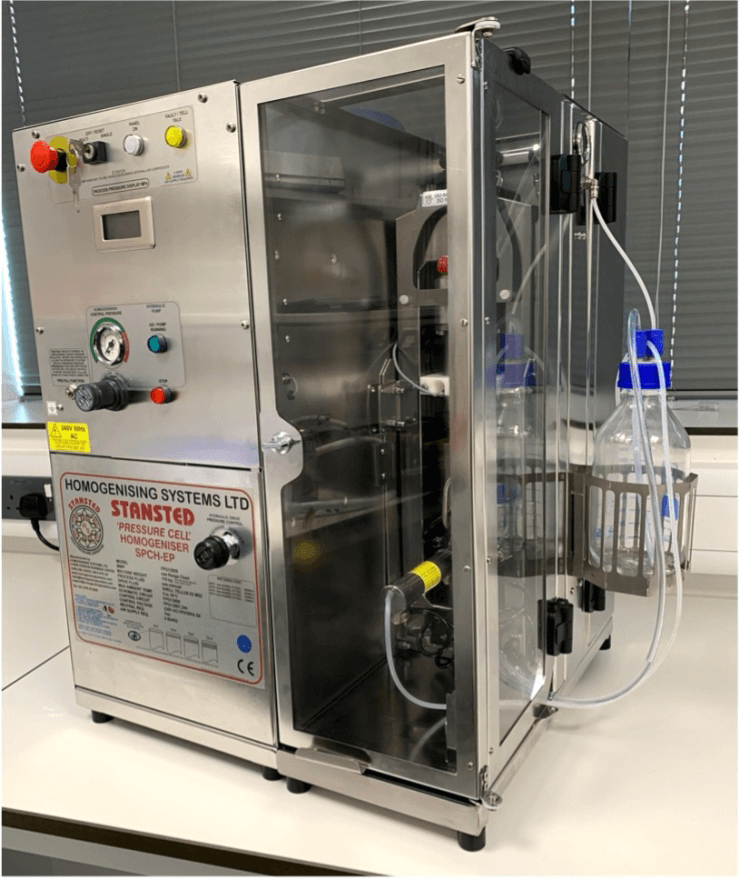

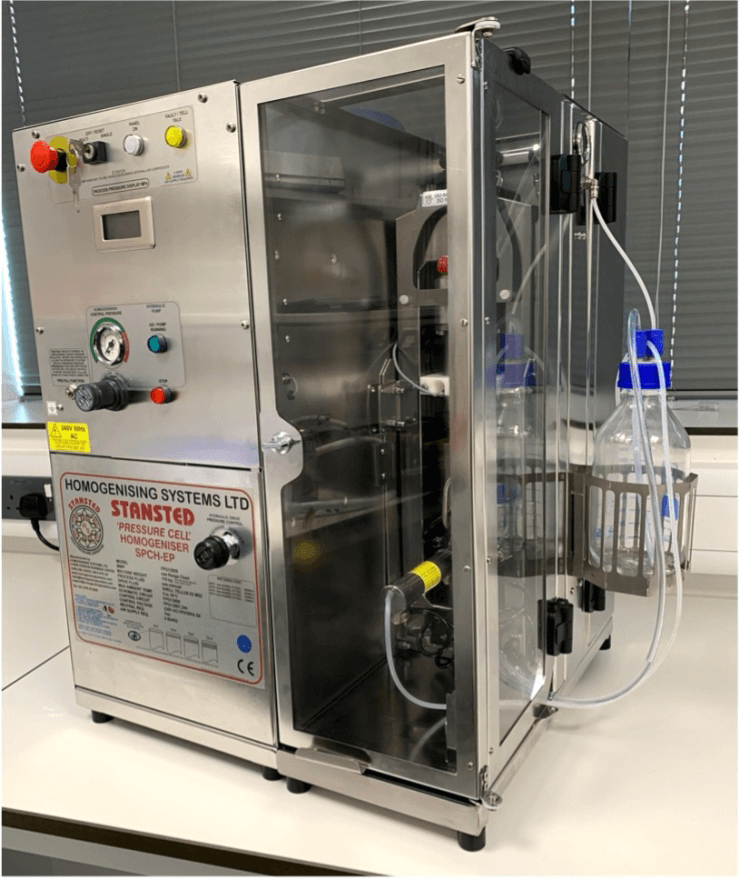

Pilot Homogenizer in a Pharmaceutical project with feed and discharge reservoirs

Homogenizer - Pharmaceutical application - Vaccine production

Production Homogenizer system

Homogenizer system for Vaccine production

用于疫苗佐剂研发和生产规模的高压、高剪切均质剂。高效加工,粒径最小,粒径分布窄。

佐剂通常用于提高疫苗的效力,从而帮助增加病人的免疫反应。

我们的行业领先技术可以创建具有可控液滴大小和分布曲线的纳米颗粒,可以无菌过滤,产量损失最小。

疫苗佐剂-我们的高压均质剂

易于扩展-从实验室研发到完整的生产系统-高达1000升/小时-具有可重复的结果。

可控,行业领先的压力高达4200 bar (60000 psi / 420 MPa)。

复杂的温度控制选项。

CIP和SIP能力。提供DQ/IQ/OQ文件。

易于清洁和消毒。CIP和SIP能力。

易于维护,持续拥有成本低。

精确的高剪切创造更小,目标颗粒与狭窄的尺寸分布。

用于疫苗研发的实验室均质机

疫苗研发实验室均质机

有进料和排料库的制药项目中的中试型高压均质器

高压均质机-制药应用-疫苗生产

生产型高压均质器系统

疫苗生产的高压均质机系统